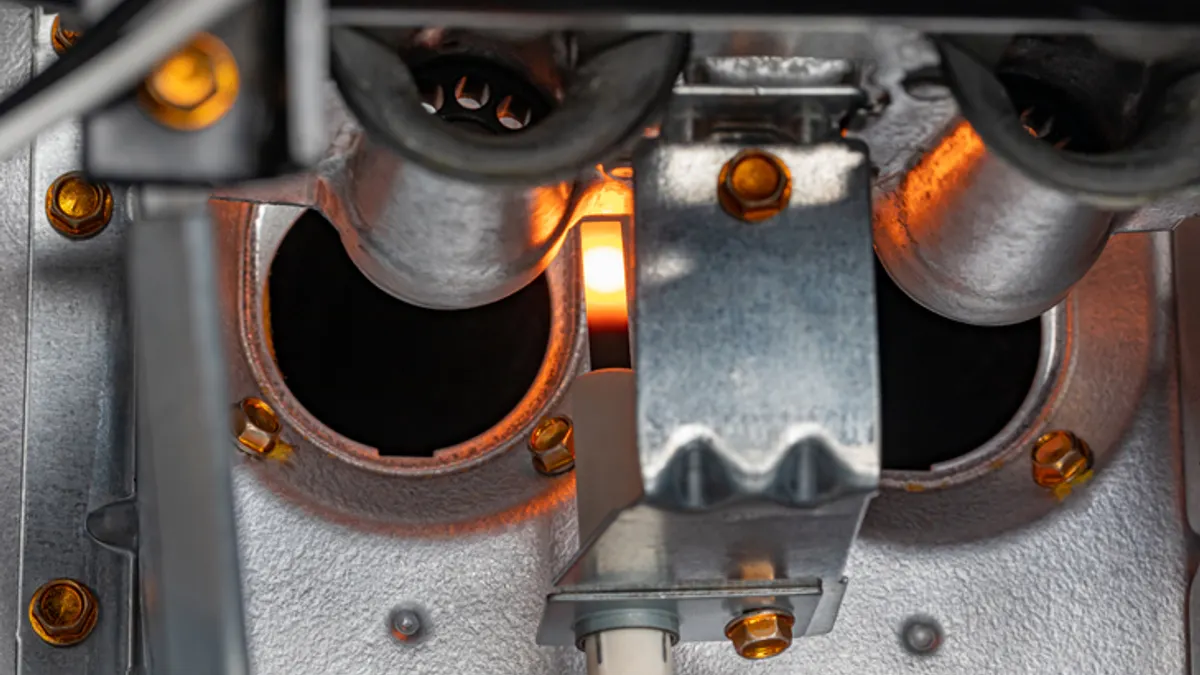

A federal rule that took effect on January 1 puts a compliance burden on managers whose facilities use HVAC systems, freezers and other appliances with as little as 15 pounds of hydrofluorocarbons refrigerant charge.

“This is definitely a new paradigm,” Steven Blumenfeld, vice president and general manager of Trakref, a cloud-based refrigerant management platform, said in an interview. There are “meaningful new responsibilities for facilities managers.”

The leak repair and management rule, which the U.S. Environmental Protection Agency finalized in 2024 and took effect at the beginning of 2026, lowers the threshold for appliances that must comply with greenhouse gas restrictions from 50 pounds of hydrofluorocarbons refrigerant charge to 15 pounds.

The rule requires facilities managers with these smaller appliances to calculate the rate at which refrigerant is leaking every time they add to the appliances more HFC refrigerants or, if they use a substitute, those substitutes with a global warming potential, or GWP, greater than 53.

“The low applicability threshold greatly expands the scope of the rule,” David Arthur Terry, an attorney with Hunton Andrews Kurth, says in a December blog post.

If the leak rate is above a certain threshold, facilities managers must make a verifiable repair within 30 days and, if they can’t do that, either retrofit or replace the appliance within a year.

That requirement “provides very little time to repair a system before a system owner must begin to plan and implement the complete overhaul, retirement, and/or replacement of their system,” Terry says in the post.

For facilities that already operate a refrigerant‑management system, the new regulatory landscape simply expands the scope — more equipment to track, more data to manage and more rigor required, Blumenfeld says. For those that don’t have a system in place, compliance will require a step-up in data collection and record keeping. That can be a challenge because the existing technologies that facilities managers rely on often operate in isolation to one another, with the HVAC system using one technology and freezers and other appliances using other technology — what Blumenfeld calls a “massively distributed problem.”

“That [management system] gap now translates into meaningful new responsibilities for facility managers,” Blumenfeld said. At the core, managers will need to keep “auditable records” or “risk compliance exposure if logs are incomplete or improperly maintained,” he said.

A typical facility relies on a computerized maintenance management system or work‑order system for day‑to‑day operations, a separate environmental health, safety and compliance platform for regulatory documentation, and yet another asset‑inventory system for equipment tracking, Blumenfeld says. At the same time, service technicians typically use their own mobile tools or contractor‑specific platforms to log activities. “The result is a patchwork of disconnected systems,” Blumenfeld said.

For facilities starting from scratch, step one is to tag all of the appliances that could fall under the compliance threshold, says Basant Singhatwadia, global director of customer success and strategy at Facilio, a multi-site facility management enterprise platform.

“The challenge is that a lot of companies don’t have refrigeration assets tagged in their systems,” Singhatwadia said in an interview. “This is a daunting and potentially very expensive problem, because you basically need boots on the ground.”

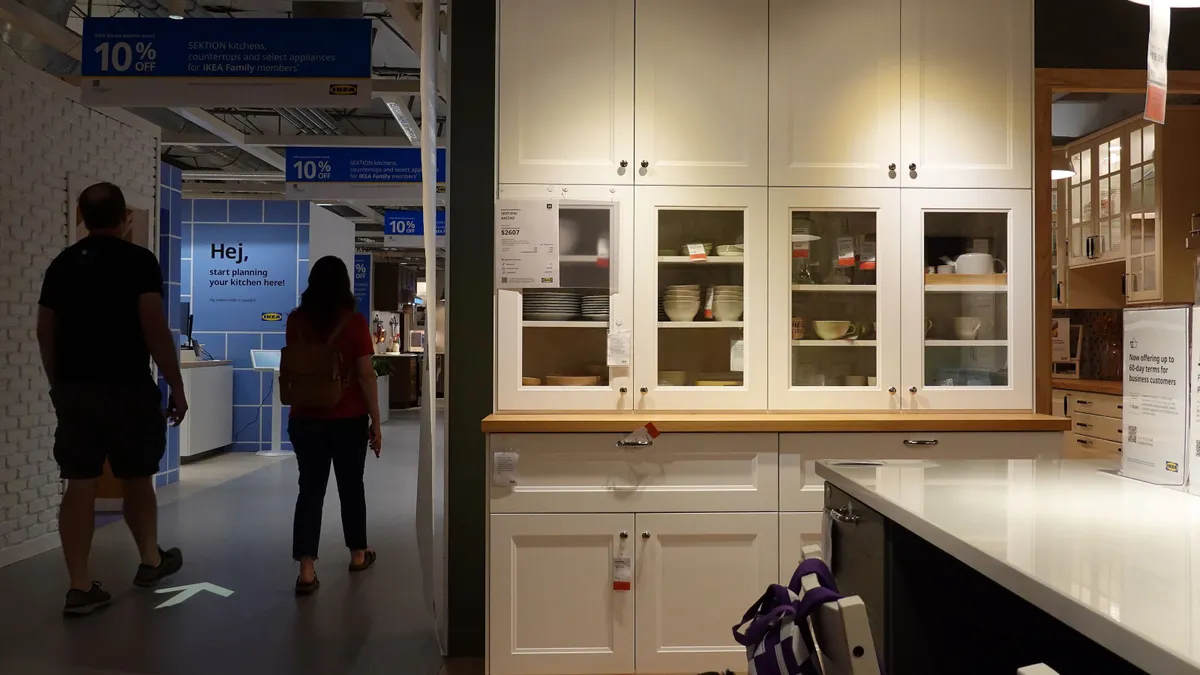

Retail facilities could be especially hard hit to the extent they’re big users of refrigerated appliances, Singhatwadia said.

Blumenfeld recommends facilities managers prepare for compliance by detailing their inventory and then evaluating each appliance to determine its exposure under the new rule. Once that’s done, they can devise a system for monitoring leaks and then put in place an audit trail for filing with the EPA.

Singhatwadia recommends facilities managers look for software that has compliance requirements built in and has a strong reporting engine. “It’s quite important because, what I've seen in the industry is that, once the year ends and the reporting period starts, people are scrambling for a month or two to generate their reports from an Excel spreadsheet,” he said. “Sophisticated refrigeration management software should be able to generate the required reports with a press of a click.”

He said advanced refrigerant management systems are equipped with AI-driven telemetry and use sensor-based monitoring to identify slow leak detection and include automated repair workflows and compliance monitoring.