Dive Brief:

- Mechanical, engineering, plumbing (MEP) and other professionals have been using building information models, or BIMs, for years to optimize the construction process. But the technology hasn’t been more widely adopted in facility management because of its complexity, researchers say in a paper published earlier this month in Scientific Reports.

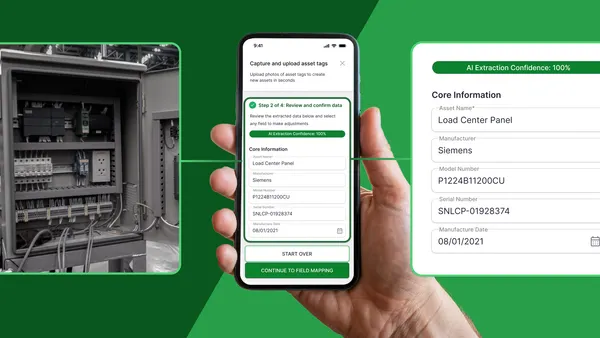

- To get over that hurdle, the researchers say, they’ve modeled what an easy-to-use decision support system plugin would look like if facility managers wanted to customize a BIM tool for their own use to optimize maintenance and budgeting.

- “Many BIM-integrated facility management plugins require specialized knowledge, making them inaccessible to non-expert users,” say the researchers, affiliated with research institutions in Cairo, Egypt. “The proposed plugin works as a user-friendly interface … simplifying facility management and increasing accessibility for a broader range of users. Additionally, unlike traditional solutions, this plugin leverages real-time data and predictive models to enhance maintenance scheduling, ensuring more efficient planning and resource allocation.”

Dive Insight:

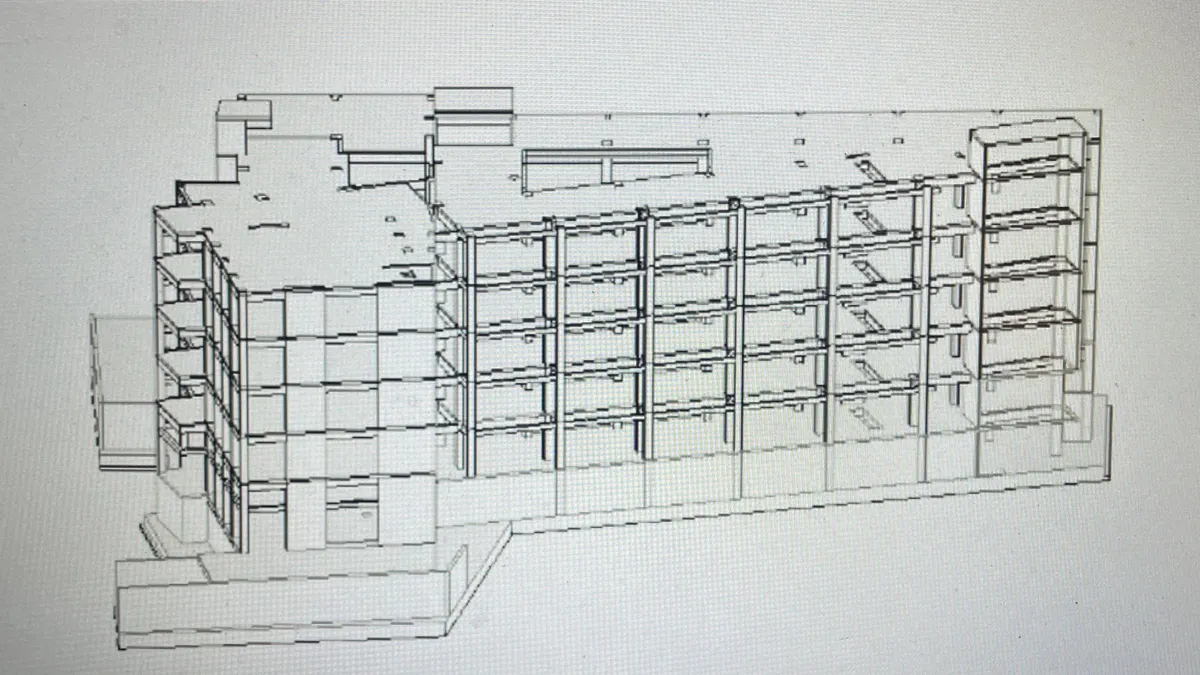

BIM tools help building professionals by creating a digital twin, or 3D representation, of their property, enabling them to manage construction, in the typical case. But with the right plugin they can also help with operations management.

“Elements like walls, doors, windows, roofs, and floors are used to create the virtual representation of the building,” the researchers said. “These elements are parametric, meaning they can be easily modified and updated…. The software [also] stores important data associated with each element (pricing, budgeting, and … maintenance [and] time-related information.”

To model their plugin, the researchers exported the BIM elements of an academic building in Aswan, Egypt, into an Excel spreadsheet and filled in the cells with data on each of the elements – building materials and mechanical systems, among other things. Data on energy use, maintenance, lifespan, replacement and other things were also included.

“The responsible engineer or a maintenance engineer should fill all the cells in the exported Excel sheet, based on their on-site inspection,” the researchers said.

The researchers imported the spreadsheet data back into the BIM and ran it through predictive modeling software. “This integration of geometry and data enables better coordination and collaboration among project team members,” the researchers said.

For facility managers who have a plugin like this created, the researchers said, they should find it possible to plan, track, and allocate their maintenance budgets with more precision.

They can also create maintenance schedules based on the facility’s condition, type of equipment, frequency of use, and allocate resources, parts and labor for maintenance. Additionally, such a BIM plugin can generate reports that show “resource utilization, expenditure, and other cost-related indicators,” they said, “making it easier for facility managers to plan their budgets and make informed decisions.”

The potential utility of these plugins are leading a number of technology providers to roll out BIM and digital twin-focused software to facility managers. KODE Labs, for example, is partnering with Prolojik Limited to give operators real-time insights into building performance. In another example, Amazon is using Trane Technologies’ BrainBox AI platform to adjust temperature control and ventilation systems autonomously to reduce energy consumption and carbon emissions.