Historically, systems such as HVAC, lighting, surveillance, A/V, access control and others ran disparate from each other, often coupled with proprietary functionalities that limited the possibilities of true information technology (IT) and operational technology (OT) convergence. Traditional platform aggregators centralized data from these disparate systems so it could be collected, analyzed and acted upon. However, few followed standardized data point tagging, making systems integration and commissioning more prone to project delays and added costs.

Organizations understand they need to redefine their approach to how they manage all building assets, sensors, hardware and software to not only maintain facility operations, energy management and space utilization but also meet high-level company goals around sustainability, environmental, social and governance (ESG) impact and global regulatory industry compliance. This requires the ongoing convergence of IT and OT to centralize all building systems into one single view and aggregate all data to drive actionable insights and data reporting.

A central intelligence manager (CIM) platform can provide one centralized command-and-control interface across the technology stack of the built environment. With four key steps, organizations can centralize disparate systems to drive optimal results and transform speed to value.

1. Establish your use cases.

Before selecting a CIM platform, it’s important to identify your use cases and what short- or long-term outcomes you want to achieve. Each use case can require integration with connected IT/OT systems, subsystems, sensors and even third-party applications. For example, you may have an immediate need to improve command and control of HVAC and lighting systems across your portfolio but see a growing need to simplify the management of your telecommunications closets. Do the existing systems connect through an open API or other standard protocol, or are they closed, proprietary systems? Do you need to add hardware to the telecommunications closets, and does your platform readily connect with those technologies?

If the complete technology stack in your built environment can readily integrate, your speed-to-value will be faster as your implementation expands to areas like energy efficiency, environmental health and space optimization. Your CIM platform should scale alongside your changing needs.

2. Evaluate site readiness.

Collecting information from multiple systems is nothing new for facility managers. But the proprietary nature of how technologies still communicate results in interoperability challenges. For example, if multiple system integrators on one job site tag different devices, such as room temperature controls, in various ways (i.e., TEMP and TP), that makes it more difficult to integrate those devices across building systems.

Harmonizing data from multiple technologies is essential. This can be accomplished by first conducting a site-readiness assessment. Identify all systems that will connect to the CIM platform to understand what communication protocols are used. Consider the need to evaluate your wired and wireless infrastructure. This is important if you plan to add new, bandwidth-intensive hardware and sensors, or implement use cases that require real-time data, support critical operations or stream video. Once this baseline is understood, you can harmonize the data, so it’s communicated in a uniform way. Data models such as Project Haystack can help standardize this process and make data from different building technologies interoperable.

3. Optimize your speed to value.

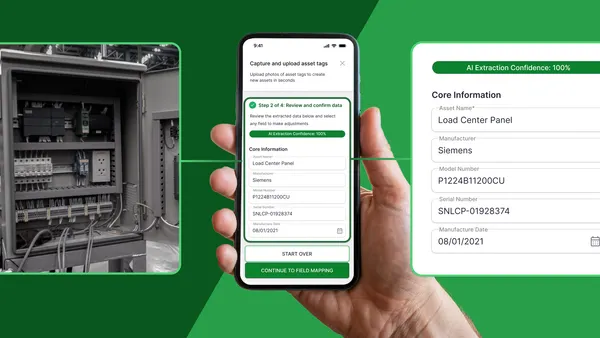

A CIM platform can be deployed remotely, which can save time and money especially if planning deployments at multiple sites. Choosing a CIM platform that reduces custom engineering work can also save time. A good example of this is a platform that has API integrations to deliver out-of-the-box connectivity with a variety of technologies and systems, in addition to the ability to add custom integrations as needed. Your platform may offer the option to import historical data to accelerate speed to insights and help set a baseline for normal operations.

4. Turn chaos into clarity.

Connected devices are only going to continue proliferating facilities, on both the IT and OT sides. Facility managers who lack the ability to view this data from one centralized platform will miss out on potential valuable insights gained from predictive analytics to reduce downtime, automate processes and improve operational efficiencies. Strategically uniting data from these technologies in a single, command-and-control platform will streamline situational awareness and fault detection, unlock opportunities to improve productivity and optimize energy consumption and space utilization, security and environmental health and safety.

Conclusion

A CIM platform delivers what many facility managers ask for – the ability to access all facility data in one place and make sense of it. Gain insights into other CIM use cases to simplify and optimize building operations and reduce costs and project complexity.