The University of Illinois Chicago is making a push to upgrade its facilities through a partnership with Ameresco that’s intended to address deferred maintenance of mechanical equipment and deliver HVAC upgrades to critical campus buildings.

The $30 million energy conservation project at UIC, one of three campuses in the University of Illinois system and the largest university in the Chicago area, includes the installation of 24 energy efficient air handling units and implementation of heating and cooling smart controls in an administrative building and a science building.

The initiative is expected to generate approximately $1 million in yearly energy and operational savings and reduce campus greenhouse gas emissions by 2,100 metric tons of carbon dioxide annually.

The upgrades are intended to address deferred maintenance at the facilities at no immediate cost and on an expedited timeline by using an energy savings performance contract, or ESPC.

“The systems here were sixty years old, and even throughout COVID and everything else, we were able to keep up them running with 100% pressure,” Sandeep Kulkarni, associate director for engineering and commissioning project management, said on a tour of the two buildings. “If you look at the ASHRAE life expectancy for [our existing air handling units], it’s 25 to 30 years. These are twice the age at 60 year old. The units have been held together with a Band-Aid.”

The need for the project was not energy, Kulkarni said. “Energy was one byproduct and originally part of the thought process,” he said. “The important thing was to get the deferred maintenance under check. There was a stationary engineer in the [University Hall] building every single day for 24 hours. That’s what the condition was in recent times for us.”

The project, which broke ground in May, is expected to take 18 months. It would have taken much longer if the university had to finance the upgrades itself to be completed across multiple years, and a much bigger headache to coordinate with students and staff, Kulkarni said.

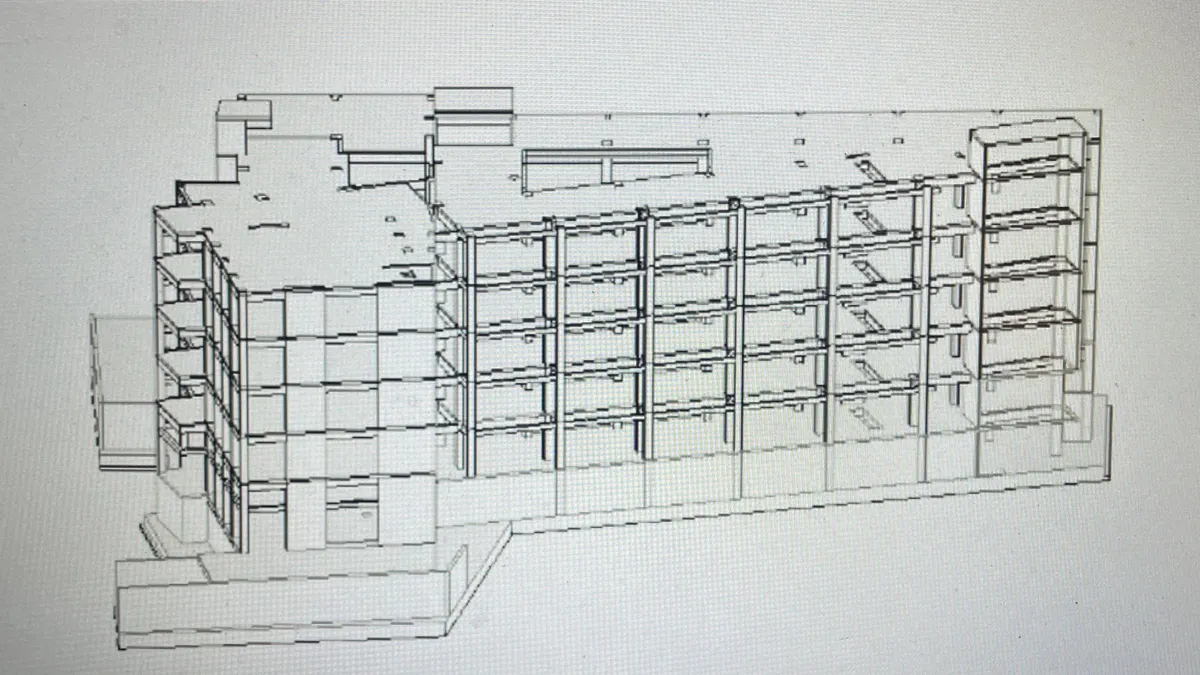

University Hall, built in the 1960s, houses administrative offices, including the chancellor’s office, while the Behavioral Sciences Building is the largest classroom building on the campus. Because of the important roles of the buildings, it was critical to get upfront funding and work with a partner to ensure the project took place in a compact timeline, instead of over years, Kulkarni said.

“It’s not about the comfort issues,” he said. “Those can be somewhat mitigated. It’s the deferred maintenance, and consistently spreading maintenance funding over the years.”

Deferred maintenance is a problem among budget-constrained higher education institutions, particularly state-funded ones like UIC, Kulkarni said.

“You’ll see this in every single campus,” he said. “Everybody is budget strapped and cannot do much. And being a state university, that’s another big part of it. One of the thoughts was, considering that we will have to replace this either way and there is a good amount of energy savings to be had, if we can capture some energy efficiency back out of it, it can be funded in a different mechanism.”

The current project is being funded by campus institutional funds, with Ameresco serving as UIC’s partner in execution to help maximize energy savings and address deferred maintenance. This work builds on UIC’s $65 million partnership with Ameresco, previously completed through an ESPC, which modernized campus systems and delivered significant efficiency gains. That work showed that a similar funding mechanism could be viable for future projects, like those at University Hall and the Behavioral Science building.

“We knew about this process in the halfway break of that [previous project], so that’s where it started,” Kulkarni said. “It turned out to be a viable project.”

To reduce disruption, Ameresco and UIC provided project timelines that included dates that certain floors would be unavailable to staff and students. For the 28-floor University Hall, this meant shutting down three floors at a time and relocating staff offices to another building.

“You take three floors at a time, and those three floors move out to a temporary location,” Vince Mazzeffi, director of construction at Ameresco, said on the tour. “There’s no coming air to each floor until we’re done. We have to add valves around so the rest of the building won’t be affected during our construction.”

Access to each room is required so thermostats can be replaced with new digital controls, according to an FAQ of the project. After the new air handling units and controls for these floors are installed and reconnected, the team will move on to the next set.

With the new units, there is more space for maintenance staff and new controls, including variable frequency drives that control everything in the AHU as well as information on filter status. “You can tell by the pressure on either side of the filter if you need to make a change. That goes back to your building automation system, so now building engineers can sit at another building on campus and monitor, Kulkarni said.

Different buildings have presented different challenges. The Behavioral Sciences Building has an expansive area in the basement that can house bigger equipment. That meant carrying in larger units, which required cutting away a portion of a wall and using a crane to drop in the equipment. At University Hall, by contrast, crews will bring in small air handling units to a single maintenance room at the end of the floor.

Installation of new equipment at the science building’s portion of the project was completed in late August, with the work on University Hall expected to be completed early next year.

“All of this gets connected over the internet to a campus central service that’s about two blocks from here,” Kulkarni said. “We maintain the server and are able to see it, so facilities can basically open to this unit while sitting in their office instead of having to go out and check.”

In addition to tackling deferred maintenance, the large-scale energy efficiency upgrades are designed to reduce consumption, costs and carbon to help drive the university’s commitment to its climate commitment target of achieving net zero GHG emissions by 2050. “It’s not easy to put together a $28 million project for something like this, for infrastructure that is not very visible to students. It’s not fancy stuff, in a way, but it’s about the necessities,” Kulkarni said.

The successful implementation of these upgrades is a result of collaboration between Ameresco and UIC’s facilities team, with constant communication and collaboration from design through installation, commissioning and operations, according to Mazzeffi. ”It’s a partnership. The electricians, chief engineers and all of the partners are involved, so there’s no surprises,” he said.

Public-private partnerships like this prove crucial in today’s market as universities and other public organizations struggle to tackle significant deferred maintenance needs and reduce energy costs, Kulkarni said. “It enables us to do projects today, in a relatively short time frame, rather than over years, which would take loads of time and logistics headaches,” he said.

Correction: This story has been updated to correct the University of Illinois Chicago’s position within the state university system and its partnership with Ameresco.