Nationwide HVAC maintenance and repair company Impact Service Group is making remote sensors available to facility managers this fall to give them real-time data on the performance of their mechanical systems, the company’s president told Facilities Dive.

The company in October is rolling out what it calls an REM device – a cellular-enabled remote equipment monitor – to help facility managers know ahead of time if a unit is faltering and, if a unit goes out, when operation is restored, Clayton Callander said. The monitor works by tracking the temperature, voltage, vibrations and sound coming from each HVAC unit deployed at a site.

“We wanted a way for facility managers to reach out and touch a piece of equipment – see live data coming from that equipment – without having to rely on phone calls and emails to know [what’s happening with a unit],” Callander said.

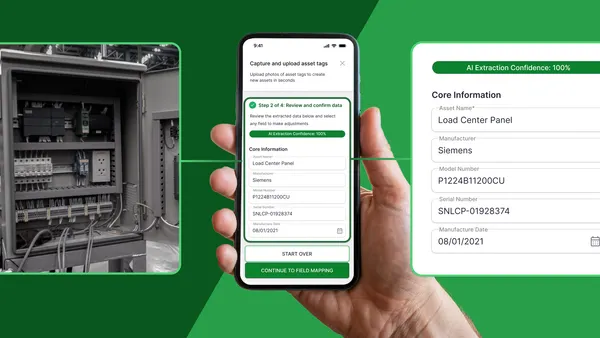

The company is also rolling out a companion platform, called Nebula, to capture and store data on each unit, giving facility managers a dashboard for managing their HVAC system.

“Nebula is basically a one-stop shop for all of their work orders, equipment lists, history, invoices – similar to a ServiceChannel or a Corrigo,” Callandar said. “The difference is, because we are only focused on HVAC, it’s tailored to that service type, and because we provide this [maintenance and repair] service, all the equipment, all the work orders have actual people doing quality assurance on the back end to make sure the data is accurate.”

Impact Service Group launched 22 years ago as a traditional HVAC services company. It relies on a nationwide network of technicians to make on-site repairs. With its remote sensor and dashboard, it’s aiming to give facility managers a way to stay on top of their systems better and help service vendors deploy their technicians more efficiently.

“Our system gives you the belt size, the filter sizes and information on the individual components inside of the unit, so if there’s a work request, the vendor already has a pretty good idea of what the problem is,” Callander said. “They can see that the unit failed four hours ago, the thermostat is calling for cooling but the unit’s not actually cooling and that right before the unit failed, the blower mower was pulling high amps.”

That kind of data can help vendors manage their time better, he said. “Instead of just showing up to the spot having zero idea how much time they’re going to spend there, working on a piece of equipment, they can know it’s probably a belt and it’s going to take about an hour and a half,” he said. “So they can schedule something for the second half of their day.”

The company is beta testing REM and the Nebula platform with about half a dozen of its customers. When the products launch, existing customers will be given access to the platform for free and the remote sensors for $500 each. The platform, like other facility management software platforms, is a useful tool on its own for managing HVAC systems, Callander said. But the company thinks facility managers will see the value of making the investment in the remote sensors as well.

“If this device just helps get rid of one second call or one overtime call, or keeps the [business] up for one day, it pays for itself,” he said. “We like to call REM the check-engine light. It provides warnings and alerts and lets the facility manager know there’s a problem. ‘I might not know what the problem is, but I know there’s a problem and I should investigate it deeper.’”