A cooler drifts out of range at 2 a.m. and nobody finds out until morning. A dining room overheats just as the lunch rush begins. Lights blaze all night in an empty retail store. For facilities managers, these are not rare exceptions—they are the daily realities of running multi-site operations without remote visibility.

And while the tickets may vary, the impact is predictable: spoiled inventory, uncomfortable customers, frustrated staff, stressful emergency truck rolls and wasted energy that eats away at profit margins and draws scrutiny from corporate leadership.

The problem isn’t a lack of effort—in fact, most facilities teams work around the clock to stay ahead of breakdowns. The problem is visibility. Without real-time access to site-specific asset data, leaders are forced into reactive firefighting, wasting more time responding to tickets and complaints than strategic future planning. And as their responsibilities grow while headcount stalls, many FMs are burning out just trying to keep up, let alone get ahead.

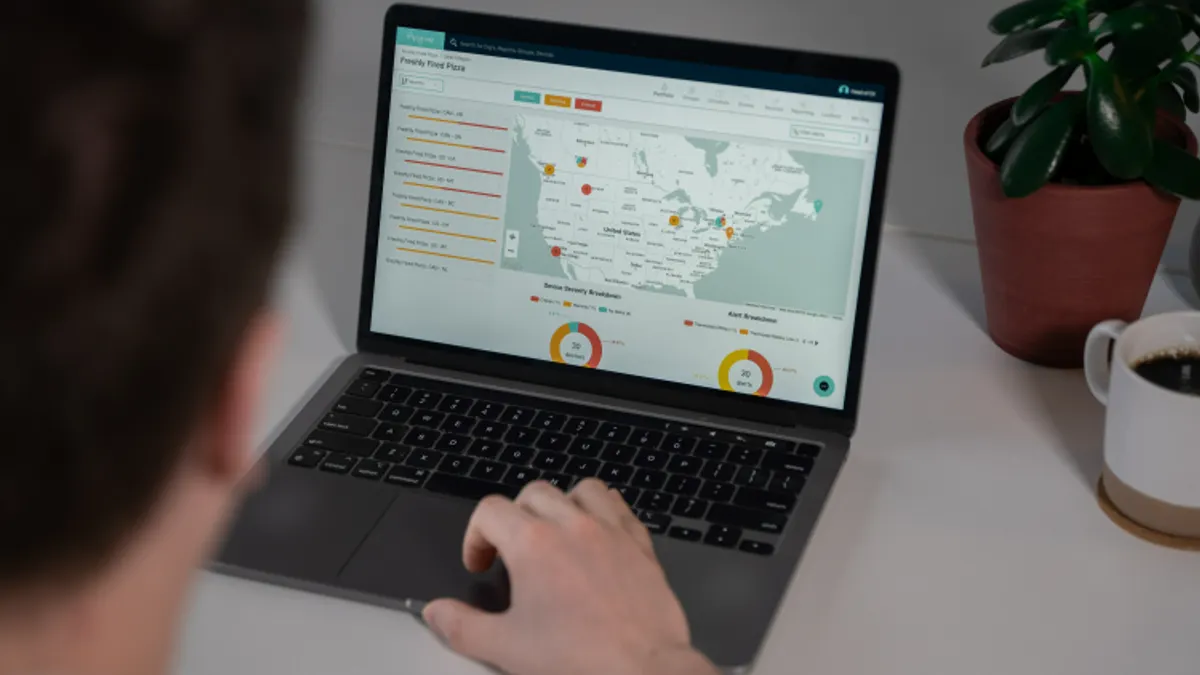

Thankfully, that’s beginning to change. Multi-site commercial facilities teams are increasingly using IoT solutions—think wireless sensors, smart thermostats and cameras that collect and transmit data via the internet to one centralized dashboard—to bring visibility, control and consistency to their operations. Centralized dashboards allow facilities teams to set, scale and enforce operating standards across hundreds or even thousands of sites, resulting in more predictable, more efficient and less stressful facilities management.

The shift isn’t about adding more technology for technology’s sake. It’s about getting “eyes on the ground” without needing someone on site. Preventing problems before they spiral into emergencies. Notifying facilities teams right away when refrigeration temperatures drift out of range, when an HVAC unit begins to short-cycle, or when lights are left on overnight, lessening the likelihood of that problem escalating into lost inventory, premature equipment replacements or unnecessarily high energy bills.

A retail financial services provider with over 400 locations throughout Canada recently implemented a lightweight EMS designed for small-box multi-sites in order to get more control over their HVAC systems and ensure employees weren’t distracted by stores that felt too hot or too cold. Fielding 300+ HVAC tickets every year, their facilities manager wanted a way to quickly address issues without rolling a truck, and ideally prevent them from happening in the first place. The impact was immediate—because he was able to implement standardized heating and cooling schedules at scale, he received fewer comfort complaints, employees stayed focused and productive, and he could rest easy knowing stores were comfortable and his HVAC systems weren’t being left on all night.

As their Senior Manager of Facilities & Property Management put it, the biggest advantage has been freeing up staff to focus on what matters most to them: “We’ve taken thermostat control out of the frontline staff’s hands, while still giving them flexibility within the ranges we set. That way, our teams can stay focused on selling, and we know the environment is managed consistently.”

Despite the measurable benefits, many IoT projects stall because of deployment complexity and cost. That’s where Mysa HQ is different. Unlike most smart HVAC controls on the market, their EMS in a BoxTM—customizable kits containing smart thermostats and wireless sensors that come pre-paired to an independent cellular network—is designed specifically for small-box multi-sites that need remote visibility and control, but can’t justify investing thousands of dollars into extensive store retrofits. The plug and play hardware means each site can typically be installed in under two hours by any HVAC technician, making Mysa HQ deployments fast and painless. With HVAC, refrigeration and lighting control and monitoring under one platform, facilities teams are able to keep an eye on their most critical systems in real-time, from wherever they are, without jumping between tools.

Many facilities managers start with HVACR control and monitoring, and for good reason—up to 60% of a commercial building’s energy is consumed by HVACR. Standardizing setpoints and thresholds across the portfolio immediately lowers both energy use and equipment wear-and-tear. Monitoring performance over time can reveal where HVACR equipment is failing, presenting compliance, inventory and food safety risks. Easy access to this data helps to mitigate surprise breakdowns, shortens troubleshooting and makes it easier for facilities managers to justify equipment upgrades to their leadership team.

For facilities managers accustomed to dealing with emergencies, the promise of IoT isn’t just fewer breakdowns—it’s the ability to stop feeling like you’re drinking from a firehose of problems, and begin managing with confidence and foresight. Learn more about how Mysa HQ is making remote HVACR management easier than you think.