If you can’t see it, you can’t manage it—and that means you’ll pay for it.

When facilities teams try to manage critical physical assets like HVAC and refrigeration remotely without visibility into performance, the losses go beyond energy waste. They ripple through productivity, revenue and retention in ways that most companies fail to measure until it’s too late.

Here are five unexpected costs multi-site companies pay when facilities managers do not have remote visibility into their HVACR systems.

Time Lost to HVAC Triage

Without remote visibility, every temperature complaint becomes a guessing game. It’s August, the store is hot and the call comes in: Did staff forget to reset the thermostat? Or is it a deeper issue, like a compressor failure? That detective work eats into hours that could be spent on more strategic or revenue-driving priorities.

When an issue does require a technician, it takes time to coordinate a fix, especially in busy seasons where go-to vendors might be busy and facilities managers are left scrambling for alternatives.

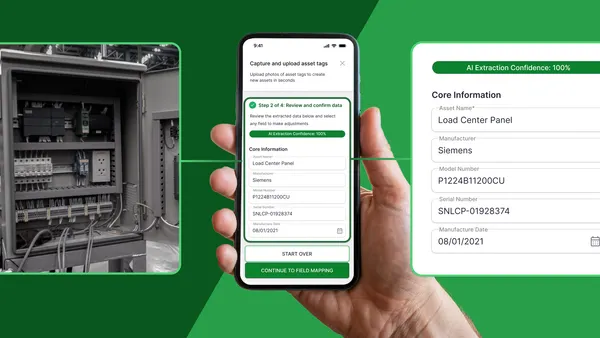

Smart thermostats and sensors help to eliminate the mystery. Real-time, targeted data gives facilities managers a window into what’s actually happening on site, so they can quickly pinpoint root causes before rolling a truck. For example, if a store is hot, in-duct air temperature sensors can reveal whether cold air is blowing from the source, or if the problem is happening downstream.

“I regularly feel like I’m on pins and needles because there are a lot of things that I don’t know, but I don’t know what I don’t know,” shared Jeremy Lombardo, Facilities Manager for Neighbourly Pharmacy, in a recent webinar co-hosted with Mysa HQ. Jeremy is responsible for a growing portfolio of 300+ retail pharmacies across Canada. “Smart thermostats and wireless temperature and humidity sensors are giving me more insight into that unknown.”

Unplanned Breakdowns

Unexpected equipment failures that call for emergency fixes often mean paying after-hours service rates, higher emergency pricing and sometimes bringing in technicians from other regions when local contractors aren’t available.

Programs that use real-time HVAC performance data have been shown to reduce maintenance costs by 25–30% and eliminate up to 75% of breakdowns. When facility managers have real-time visibility into HVAC metrics such as run-time deviations, temperature delta trends or unexpected energy spikes, they can spot the early warning signs of issues before they snowball.

“Early detection is the most cost-effective way of fixing a problem,” Jeremy explains. “I’m able to identify an issue when it’s small and repairable and avoid a full system failure in the middle of a heat wave.”

Instead of reacting to emergencies, facilities management teams can schedule service calls strategically, bundling repairs into preventative maintenance visits when service crews are already on-site and before comfort, operations or revenue are impacted.

Employee Productivity Drain

Across 400 sites, asking employees to spend just two minutes twice a day adjusting thermostats can add up to 26 hours each day.

And when HVAC systems underperform, the productivity toll may be even greater. Research from ASHRAE has suggested that every 1.8°F (1°C) deviation from ideal indoor temperature may reduce an office worker’s productivity by 2–4%.

“I tell my team that we should always be trying to make our frontline staff’s job easier and keep them focused on the task at hand, which is selling,” says the Senior Facilities Manager for a retail financial services chain with 400+ stores nationwide. “Every second they’re distracted by a facilities issue reduces revenue per full-time employee.”

Employees forced to work long hours in chronically hot environments burn out faster and call in sick more often, consequences that don’t directly appear on a balance sheet but hit operations hard. In physically demanding environments like restaurants, where kitchens are already heat-intensive and notorious for poor airflow, that discomfort translates into slower service, lower morale and higher employee turnover.

Comfort Equals Revenue

A poorly performing HVAC system doesn’t just affect employees—it drives away customers.

A dining room that’s too warm in August means shorter stays and fewer repeat visits. In retail, customers spend less time browsing, leading to smaller basket sizes and lower conversion rates.

A study out of Singapore found that extreme outdoor weather conditions—think heat waves over 95 °F (35 °C) or cold snaps below 5 °F (−15 °C)—can actually increase retail revenue by 4-11%. The idea is that when it’s uncomfortable outside, consumers flock to climate-controlled spaces. Capitalizing on this behavior means ensuring your facilities actually provide reprieve from the elements.

As the Regional Facilities Services Manager of a popular restaurant chain with close to 700 locations across the U.S. put it: “The goal is to get in front of mechanical HVAC issues before a store hits 90 °F on a Friday evening and customers start walking out.”

Burnout Behind the Scenes

A 2024 report found that work orders have risen 55% since 2023, while 42% of facilities teams reported being understaffed. Add in 12-hour days, 24/7 availability expectations and budgets that are expected to stay flat year over year, and burnout becomes inevitable.

In fact, it’s reported that 35% of facilities professionals cite “job stress” as the leading cause of leaving the field.

For women, the strain may be even greater. The 2024 IFMA report: “Factors Impacting Retention and Advancement of Women in Facility Management” suggests that since women are more likely than men to shoulder significant caregiving responsibilities at home (like looking after children or taking care of an aging parent), the need to respond to unexpected breakdowns during personal time becomes less feasible. This may explain why women represent one-third of entry-level facilities managers, but just 15% of senior executives.

In 2018, an estimated 40% of facility managers were expected to retire by 2027, and too few have entered the field since to replace them. Giving facilities management teams tools that help to reduce emergencies and restore control is critical to retaining talent—and the institutional knowledge and skills that come with them—long-term, as well as attracting new generations who consider work-life balance a non-negotiable.

See What’s Really Happening

Stop flying blind. Find out how solutions like Mysa HQ are giving facilities teams the visibility and control they need to cut HVAC chaos: standardized and automated setpoints, equipment performance data and real-time alerts, surfacing issues quickly and preventing emergencies before they start.