Dive Brief:

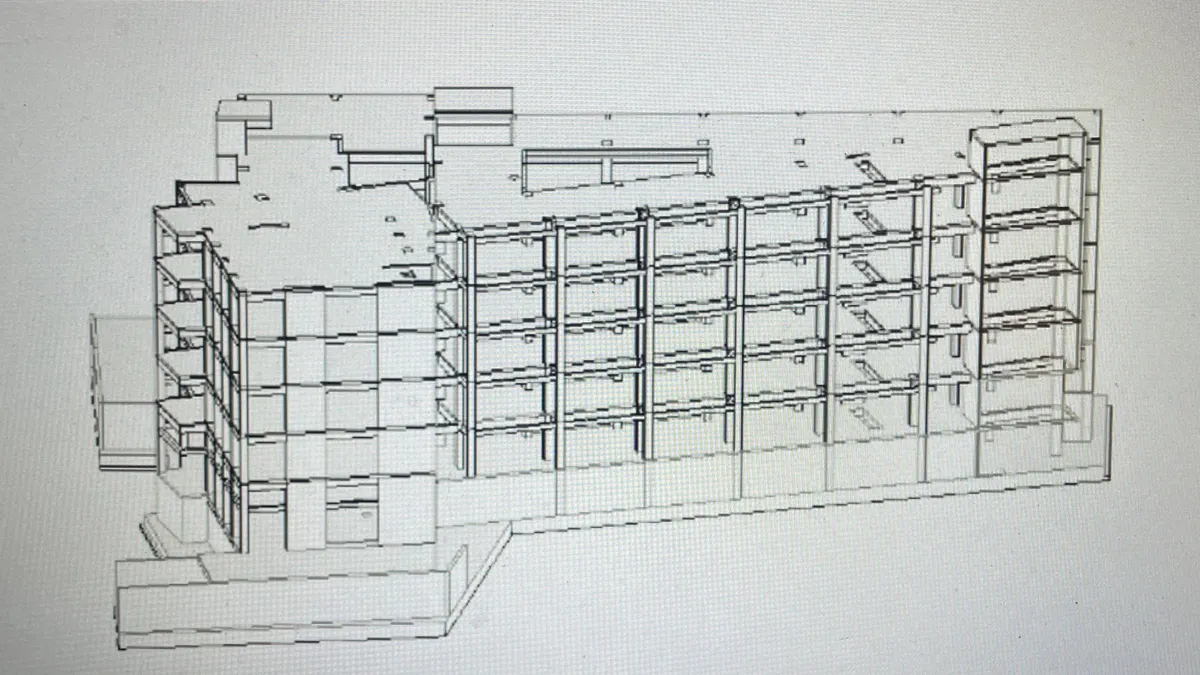

- A new type of “heat processing unit” could slash data centers’ exterior mechanical footprint up to 80% and reduce energy demand by 25% over conventional air cooling systems, its developer said last month.

- Instead of water or synthetic refrigerants, Karman Industries’ 10-megawatt, modular HPU uses carbon dioxide as a cooling fluid. In colder climates, it can reuse server racks’ waste heat to provide additional cooling capacity, boost onsite electricity generation or support nearby district energy systems, the company says.

- Karman Industries plans to deliver its first HPUs in the third quarter of 2026. “The HPU leverages 800V DC architecture while borrowing the latest innovations in rocket turbomachinery like metal 3D-printing,” CJ Kalra, Karman Industries’ chief technology officer and co-founder, said in a statement. “[It also uses] electric vehicles innovations like high-speed motors and Silicon-Carbide power electronics technology."

Dive Insight:

Traditional designs for large-scale data centers require massive amounts of water and vast outdoor tracts to host mechanical and electrical equipment, plus miles of piping and wiring inside the buildings. A typical facility might need more than 500 mechanical chillers and dry coolers, Karman Industries says.

The physical footprint, visual impact and resource consumption associated with these designs have fueled a backlash against data centers in many parts of the country. Data center developers canceled at least 25 proposed projects in 2025, four times as many as in 2024, according to a Heatmap Pro analysis.

David Tearse, Karman Industries’ cofounder and CEO, said in a statement that his company’s HPUs will help data center developers get projects up and running faster than has been happening.

“We eliminate the ‘snowball effect’ of infrastructure complexity, allowing hyperscalers to move from ‘shovels in the ground’ to ‘chips in the rack’ many months faster while unlocking additional compute,” he said.

Karman Industries says its HPUs are compatible with 800-volt, direct-current data center architectures, which chipmaking giant NVIDIA says are key to supporting the megawatt-scale server racks expected later this decade. The current 54-volt standard begins to hit its physical limits at about 200 kilowatts per rack as the required electrical infrastructure crowds out “compute,” NVIDIA says.

The HPUs may also address future regulatory barriers to data center deployment at the local, regional and even national level.

The units use carbon dioxide as a coolant rather than water or synthetic refrigerants known as HFCs — fluids that include PFAS compounds, popularly known as “forever chemicals.”

Water-based cooling systems, particularly those driven by evaporation, have drawn data center opponents’ ire in areas with limited ground or surface water resources. Karman Industries touts its design as key to “future data center architectures where massive water consumption is not an option.”

HFCs face growing scrutiny — and regulation — due to their intense planet-warming potential. Some HFCs have a global warming potential hundreds or thousands of times greater than carbon dioxide, which has a “GWP” of 1.

Last month, the U.S. Environmental Protection Agency lowered the threshold for appliances using HFC coolants to comply with federal leak detection, repair and replacement requirements. The new threshold is 15 pounds of HFC charge, down from 50 pounds. Federal legislation that requires an 85% phasedown of HFC production and consumption by 2036 is likely to push data center developers away from designs that use these coolants, according to a Pillsbury Law analysis published in May.

Fluids containing PFAS are effective refrigerants and coolants due to their low evaporation point and fire resistance, particularly in two-phase cooling systems well-suited to high-density server racks. But legislators in at least 30 states have proposed or enacted laws restricting their use amid growing awareness of their harms to human health and long-term persistence in natural environments. Some PFAS compounds have high GWPs, as well.

Some Karman Industries competitors say there’s more nuance to the PFAS coolant story, however. In a 2024 whitepaper, Accelsius said its two-phase cooling systems use low-GWP compounds that — if vented — break down in a matter of days into a class of byproduct that has thus far not been shown to significantly impact human health.