Dive Brief:

- One Minnesota county’s vision to decarbonize a 15-building district energy system faces economic and practical difficulties in the near term, two people involved in the project said at the International District Energy Association annual conference earlier this month.

- Eliminating steam completely was infeasible, with a major safety net hospital as the top customer for the Hennepin County system’s well-maintained steam loop,, and switching to electric boilers would likely be prohibitively expensive, said James Bohn, principal with FVB Energy.

- Over the longer term, Hennepin County envisions serving a major planned hospital expansion with an electric-powered heat exchange system, backed up by the current mix of electric and fossil-fuel equipment, which could eventually run on renewable natural gas as markets develop for that fuel, Bohn said.

Dive Insight:

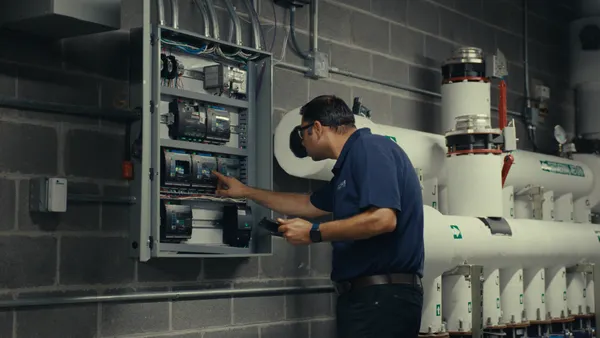

The Hennepin County Energy Center supplies high-pressure steam and chilled water to six county-owned buildings and several private customers in downtown Minneapolis, including the hospital. The county, Minnesota’s largest, aims to reduce the facility’s environmental impact over time as it targets a 45% reduction in greenhouse gas emissions by 2030 and net-zero emissions by 2050.

Bohn’s analysis considered a “range of potential options” for near-term decarbonization, including building efficiency improvements, alternative steam sources and a switch from steam to a hot water loop, he said.

With Minnesota progressing toward its legislative mandate of 100% carbon-free electricity by 2040, focusing on electrifying as much of the system was tempting, Bohn said. But the hospital’s strict reliability requirements and its use of steam for other critical processes, such as instrument sterilization, made it impractical to eliminate steam in the near term, he said.

“You can’t just go into a hospital and say we’re going to change things [and] and you’re going to be up ‘most’ of the time,” Bohn said. “You have important stakeholders who have a vote.”

The hospital’s heavy steam use and the system’s good condition means a hot water conversion is not economical in the short term, said David McNary, assistant director of environmental services with the Hennepin County Department of Environmental Services.

“Dave has done too good of a job” maintaining the system, Bohn joked.

With a full conversion from steam to hot water off the table for the moment, Bohn and McNary looked at what it would take to swap the facility’s fossil-fuel boilers for electric boilers.

They concluded that it would be prohibitively expensive — around $480 per ton of carbon saved, Bohn said. Neither Minnesota nor the United States has a formal carbon pricing scheme; the U.S. Environmental Protection Agency under President Biden proposed a $190/ton carbon price. In May, the Trump administration directed federal agencies to stop considering the cost of carbon pollution in most situations.

In contrast to its fossil-fuel boilers, HCEC’s two steam chillers — which use about 16% of the energy produced by the boilers, Bohn said — are comparatively low-hanging fruit for decarbonization.

Next year, the county will begin planning for the 2029 deployment of York steam chillers that are expected to cost about $9 million upfront and require no significant infrastructure upgrades, McNary said. The new chillers will reduce the facility’s direct carbon emissions by 26%, according to a slide shown at the presentation.

The conversation among energy-intensive facility managers has shifted from “how can we go 100% carbon free right now” to “how can we get 80% of the way there cost-effectively and then keep the momentum going,” Bohn said.

One seemingly simple step that could reduce HCEC’s carbon emissions by 18% — procuring renewable energy from Xcel Energy, the local power utility — has yet to happen, Bohn said. The goal was to begin those purchases in 2023, but demand for clean power is so high in the region that Xcel remains backlogged.

“You don’t just fill out a form and send it in” to start the clean electrons flowing, Bohn said.

Full decarbonization at HCEC may involve still-nascent technologies like renewable natural gas, green hydrogen or carbon capture, according to McNary. The county is looking at building an anaerobic digester to supply its own RNG, he said, but for now would need to purchase it from third-party suppliers.

That would be expensive — anywhere from $2 million to more than $3 million more per year than fossil gas, McNary said.

“That’s basically a nonstarter,” he said. “[But] I think there’s a scenario where RNG gets cheaper and more viable over time. We’ll get together in five years and see what happens.”